The Lean Manufacturing Pocket Handbook

Kenneth W. Dailey

BOOK REVIEW

In the fast-paced world of manufacturing where efficiency and precision reign supreme, The Lean Manufacturing Pocket Handbook emerges as a beacon of clarity. Kenneth W. Dailey encapsulates the principles of lean manufacturing into a compact guide that not only educates but also inspires action. This isn't just another technical manual; it's a toolkit designed for those poised to transform their business operations.

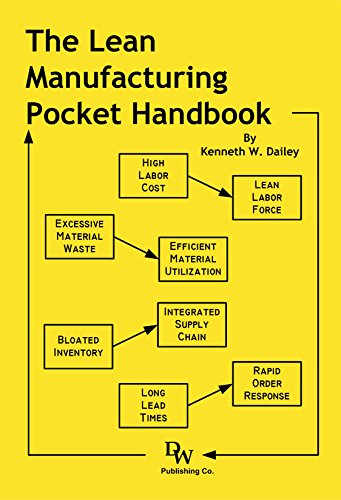

Lean manufacturing isn't merely a set of practices; it's a philosophy that can redefine the very essence of an organization. Dailey's handbook condenses expansive concepts into actionable insights, inviting readers to explore the powerful methodologies that have reshaped industries worldwide. From eliminating waste to enhancing productivity, each page pulses with the promise of potential-a promise that anyone in the manufacturing sector simply cannot afford to ignore.

As you dive into this 44-page treasure, you'll grapple with the core tenets of lean production. You're not just skimming the surface; you're prompted to challenge outdated norms and embrace continuous improvement. The handbook serves as a clarion call for those suffocated by inefficiency, breathing life into the assembly line and revitalizing manufacturing workflows. This pivotal resource serves as both your map and compass in navigating the relentless seas of industrial competition.

What sets Dailey apart is his ability to distill complex theories into relatable concepts, enabling readers at all levels-from floor managers to executives-to grasp and implement lean principles effectively. You will encounter practical tools, real-world examples, and strategic frameworks that beckon you to act. For instance, the focus on value stream mapping hones your understanding of processes and helps identify bottlenecks with surgical precision. Such insights can ignite a spark in teams, driving them towards higher efficiency and quality outputs.

But let's not soon forget the critiques; as succinct as it is, some readers have lamented that the sheer brevity of the handbook might leave them yearning for deeper exploration. In a world flooded with lengthy tomes, this handbook dares to be concise, yet it's precisely this brevity that stirs both fascination and frustration. Readers have commented on the need for supplementary material to complement this guide, highlighting that while Dailey's offering is impactful, it's often seen as just a starting point rather than a comprehensive manual.

In this digital age where information is at our fingertips, the handbook's practicality is a double-edged sword. Some find the lack of expansive case studies or advanced analytics a limitation, suggesting that aspiring lean practitioners may need to seek additional resources to fully realize the transformation Dailey champions. Yet, isn't it thrilling to consider that this small handbook could catapult you into endless learning?

Moreover, Dailey's perspectives are enriched by historical context. As the manufacturing landscape shifts-particularly in the shadow of globalization and technological advancements-the principles outlined in this handbook resonate louder than ever. Industries that fail to adapt are often left in desolation, a stark reminder of the consequences of stagnation. The call to lean manufacturing, thus, is more than just a technical recommendation; it's a necessary evolution in a world fiercely driven by efficiency and quality.

As you read, let the principles of lean manufacturing sink in, allowing them to challenge your preconceptions. This handbook isn't just about production; it's about empowerment. It's about cultivating a mindset that thrives on improvement, innovation, and collaboration. Dailey has given us the ammunition to not merely survive the relentless tides of competition but to thrive and lead.

What if I told you that within these 44 pages, you hold the key to revolutionizing your manufacturing strategy? As you turn each page, feel that urgency wash over you-will you seize the knowledge, or will you allow it to slip through your fingers? The decision lies with you. Embrace the lean methodology, and transform your understanding of what manufacturing can achieve with this pocket-sized powerhouse of insight. Don't let this opportunity pass you by; your journey into a more efficient future has just begun. 🌟

📖 The Lean Manufacturing Pocket Handbook

✍ by Kenneth W. Dailey

🧾 44 pages

2003

#lean #manufacturing #pocket #handbook #kenneth #dailey #KennethWDailey